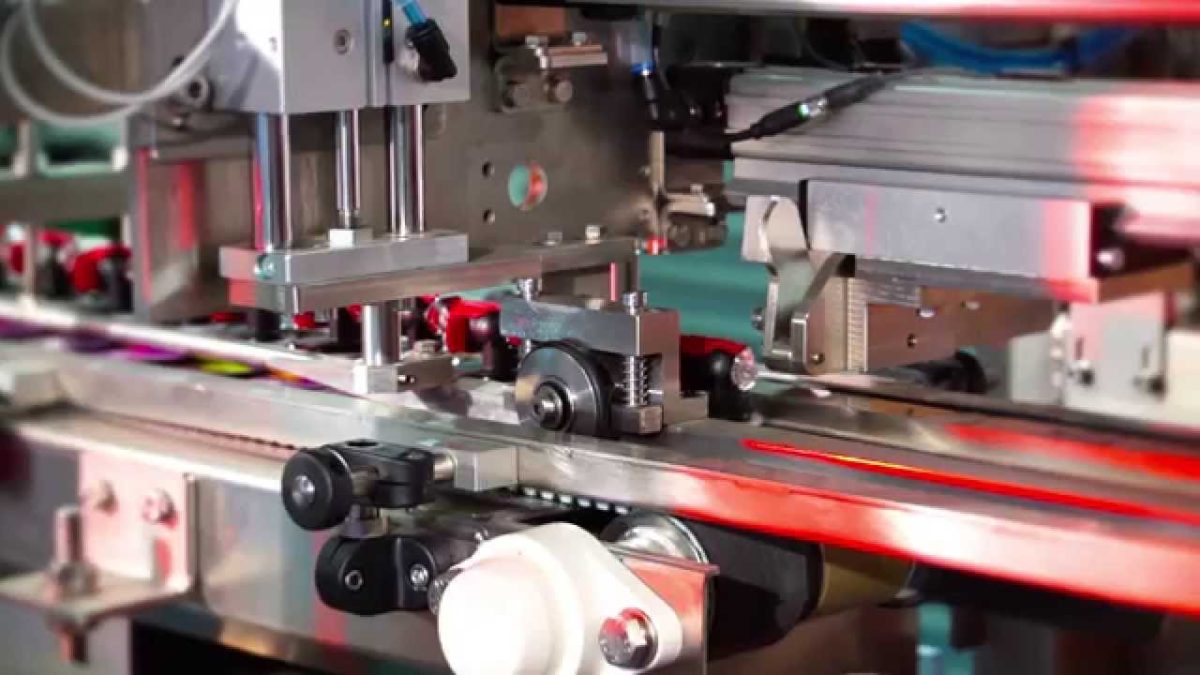

When it comes to the technology that has benefited the packaging industry in the last few years, it is undeniably automation. High-quality automated bagging systems such as bag-filling machines can be specifically valuable for businesses dealing in granule packing. These bagging machines help in easing packaging operations in several ways as they grab bags or pouches, fill them with the products, and seal them. The packed bags are then transported from the warehouses. This article discusses the benefits of investing in reliable automatic bag-filling machines for businesses.

Applications of automatic bag-filling machines

The automated bagging systems are specifically designed to deal with granular products, including rice, plastic granules, pulses, animal feed, seeds, soybeans, or maize. Following mentioned are several ways in which automatic bag-filling machines can be used:

- Filling

As the core function, an automatic bag-filling machine adds granular products into smaller bags or pouches. This machine is ideal for filing food items or other products in different weight quantities, ranging from 5 kg to 100 kg. Automatic filling of products further enables businesses to meet regulatory and compliance norms concerning the proper packaging of products.

- Sealing

Once the desired quantity of produce is filled in the bag or pouches, they are sealed by the automatic bag-filling machine. Moreover, as per regulatory norms governing the food and packaging industry, consumers should not buy products that have broken seals. Sealing products with automated bagging machines further helps avoid external interference that could tamper with their quality or weight.

Benefits of automatic bag-filling machines

Here listed are the benefits that a packaging business can avail of by investing in automated bagging systems:

- Efficiency

Packing the products manually can be a cumbersome and time-consuming task. Moreover, this process is prone to human errors resulting in inefficiencies. However, with the help of automatic bagging machines, businesses can expect efficient and improved production levels. And with better production, companies can meet production deadlines.

- Accuracy

Achieving accuracy while bagging products is vital to meet the production standard and regulatory norms. It also results in improved customer satisfaction and high profits for businesses. With automatic bagging machines, the chances of human errors are reduced, and efficiency is increased.

- Labor costs

Packaging companies can reduce their labor costs by automating their bagging process. Workers will no longer need to work on time-sensitive tasks which will further eliminate the likelihood of errors. Not only labor costs but also employees will save time and can use it to complete other essential business tasks.

Conclusion

With this article, it can be concluded that there are several benefits of investing in automatic bag-filling machines as they help companies improve their production processes and earn better profits. However, not all automated bagging equipment is designed and manufactured the same. Only a high-quality bagging system with the necessary features can help bag products efficiently. The technology supported by the machine, brand, model, production capacity, power consumption, type of bags or pouches supported by equipment, quality compliance, and safety are some significant factors to consider when selecting the automatic bag-filling machine.

Related posts

Recent Posts

- ETF Trading Algorithms: Advanced Automation Strategies for UAE Traders April 11, 2024

- Discover the Advantages of Hiring a WordPress maintenance agency March 27, 2024

- Exploring Abrasion Resistance with Dual Rub Testing Technique October 2, 2023

- Olugbenga Agboola: Pioneering African Technology through Flutterwave September 16, 2023

- Mastering SMS Campaigns: A Comprehensive Guide to Success September 15, 2023

Archives

- April 2024

- March 2024

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- December 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020